High-performance eddy current testing system for complex quality and process control tasks

- Reliable semi-finished product testing

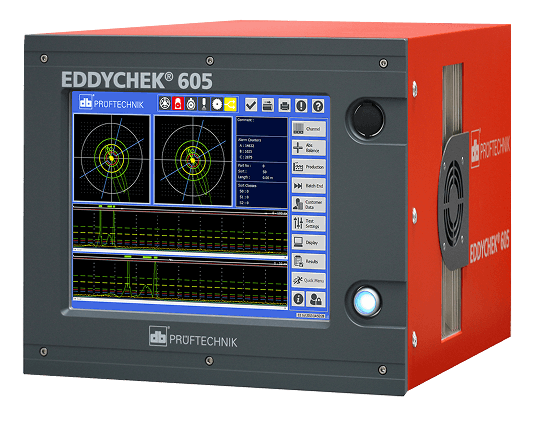

- Intuitive graphical user interface

- Robust housing for harsh environments

- EDDYCHEK 605 and EDDCHEK 610 available for different testing complexities

Flexible, future-oriented, and investment security

- Easy to use with large buttons on a high-resolution touchscreen

- Intuitive operation with a shallow, straightforward menu structure

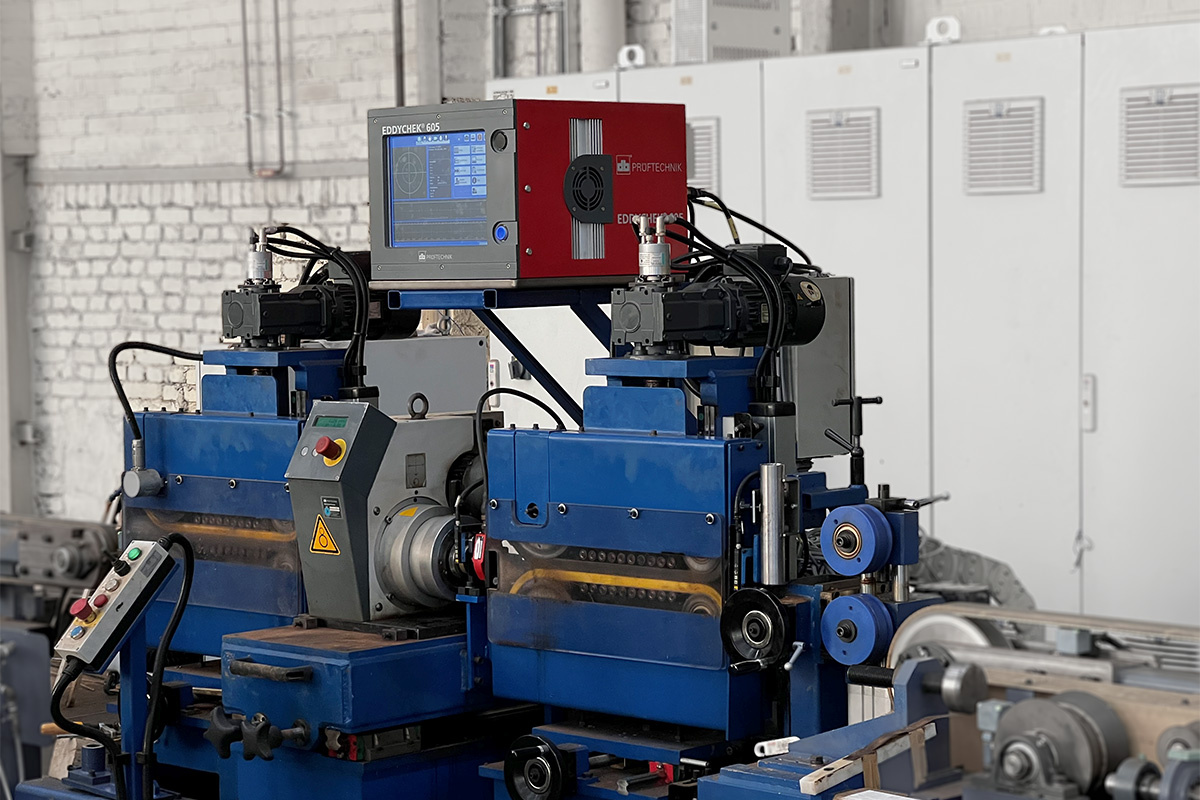

- High productivity due to high throughput speeds (e.g. with rotating systems)

- Patented, fully digital signal processing for test frequencies from 1 kHz to 1 MHz, which makes it suitable for every testing task

- High spatial resolution for the marking of faults and reduction of false scrap

- Interfaces for communication with system controls

- Full display and documentation of test data and results on the eddy current tester during testing

- Operation without air-conditioning up to an ambient temperature of 40 °C

- Ease of service with few, simply replaceable components

Product description

The EDDYCHEK 6 series with advanced, future-oriented technology and scalable design delivers high testing performance – ranging from classic crack detection with an encircling coil, weld seam inspection, complex testing tasks involving multiple sensors, up to high-speed inspection using a rotating system with automatic distance compensation. It ensures reliable semi-finished product testing and has the flexibility needed to handle a wide variety of even complex testing challenges with ease. A state-of-the-art, intuitive user interface simplifies control over numerous configuration options. Modern interfaces enable seamless integration into a network environment and full access to all test data across your network. Modular architecture – supporting a number of independent channels in several eddy current modules with a wide range of freely configurable inputs and outputs plus a full range of accessories – allows for easy expansion and adaptation to meet evolving customer requirements. Standard features include marking, sorting control, and integration into system environments. Regardless of production speed and required signal resolution, no control information is lost. Featuring patented, fully digital signal processing, the EDDYCHEK 6 series delivers the flexibility needed to meet testing demands – today and in the future – as well as secure investment in your production infrastructure.

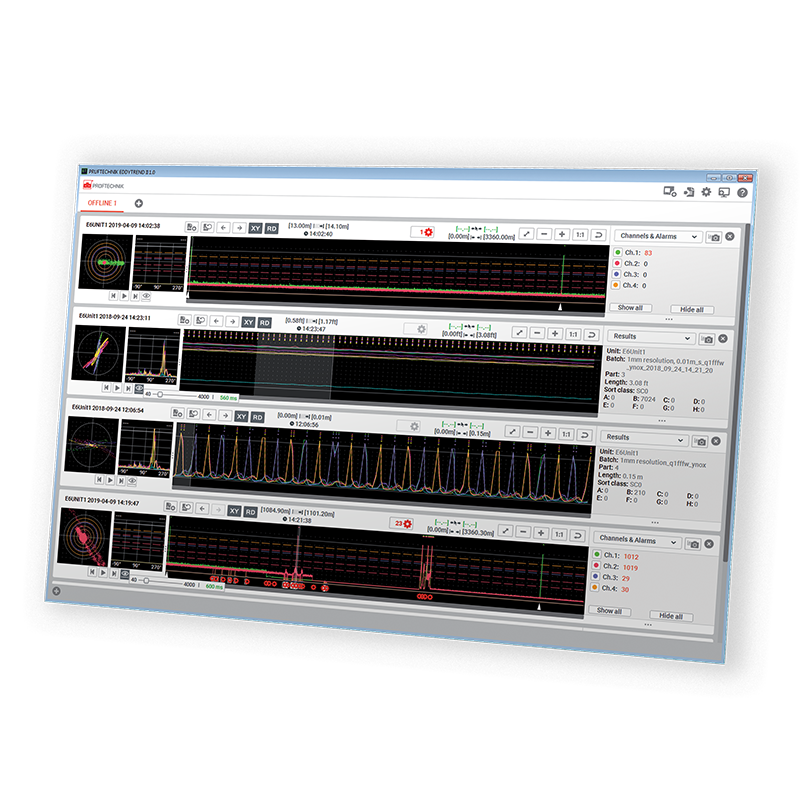

Visualizing the test signals on a PC screen while the inspection process is running, the EDDYTREND II software is available to serve as a virtual recorder. EDDYTREND II makes it possible to analyze and print out the data or to save them for documentation purposes as and when required. It can also display selected archived data at a later point in time, e.g. for auditing historical test data.

Features of the EDDYCHEK 605

- Economical and efficient

- All-in-one eddy current tester

- Dustproof industrial housing IP52

- Up to five independent testing channels and up to three eddy current testing positions

- Up to 12 freely configurable inputs and outputs

Features of the EDDYCHEK 610

- Top-of-the-range eddy current tester

- Dustproof industrial housing IP52

- Up to ten independent testing channels and up to six eddy current testing positions for more complex testing scenarios

- Up to 16 freely configurable inputs and outputs for connecting a wide range of peripherals

-

EDDYTREND II

Search, visualize and analyze eddy current inspection data

Interested?

Our technology experts are happy to answer your questions!