Designing, planning, construction, installation and commissioning

- Single-contract turnkey system

- From planning to installation

- Complete test tracks or individual test sections

Conveyors – Transport system for NDT applications

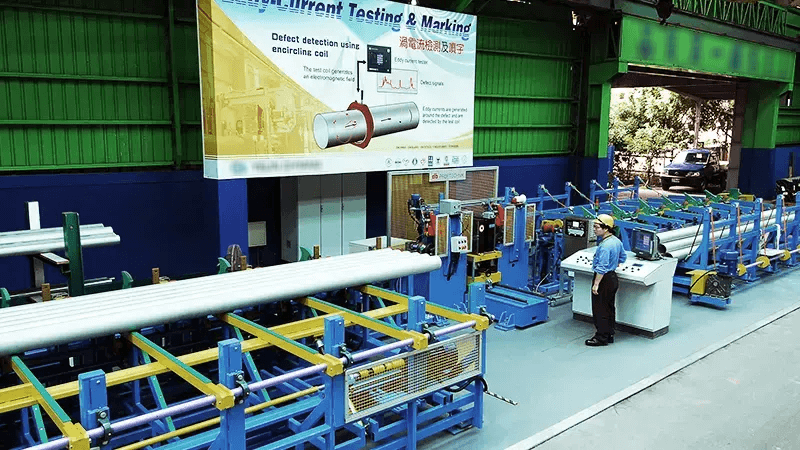

For offline testing, PRÜFTECHNIK NDT plans and supplies complete conveyor systems used in transporting the product to be tested. The conveyor is customized to meet product specifications, space limitations and sorting requirements. It consists of an infeed conveyor, a testing table, an outfeed conveyor and a sorting system using belt troughs. Optionally, PLC-controlled transfer arms enable automatic sorting. The sorting system can distinguish between several product quality grades.

Testing tables – Tables for NDT applications

All the units required for eddy current testing in the production line can be placed on a convenient testing table. The testing table is customized to meet on-site specifications and is often integrated in the conveyor. It can be raised or lowered to the level of the tested material. The units it holds depend on the application:

- Centering triples for guiding the test piece

- Eddy current test coil

- Marker, encoder, magnetization and demagnetization units

The test coil holder, magnetization unit or rotating system is usually mounted on a sliding table to pull it out of the line for changeovers and/or service.