Equipment for encoding, alarms, marking, and calibration for eddy current testing

- Practical and smart

- Robust design

- Broad variety

-

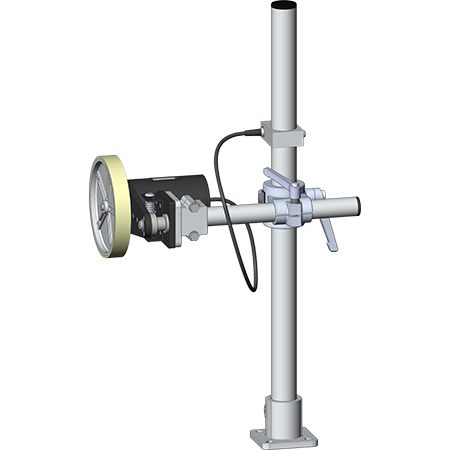

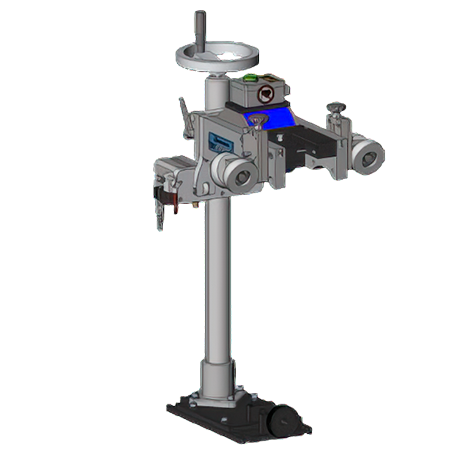

Encoders

Pulse encoder for defect marking, sorting, and data reports independent of line speed. Robust design available for harsh testing environment. -

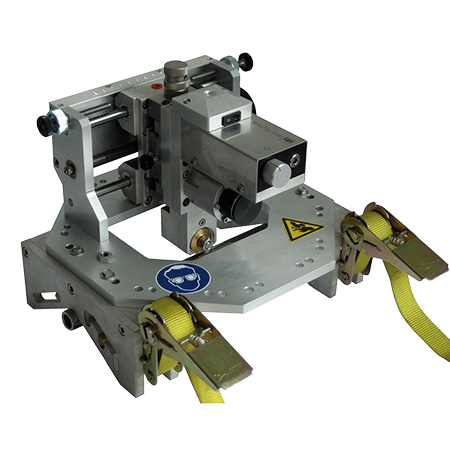

Test defect saw

Portable unit to saw standard defects in tubes, rods, and billets -

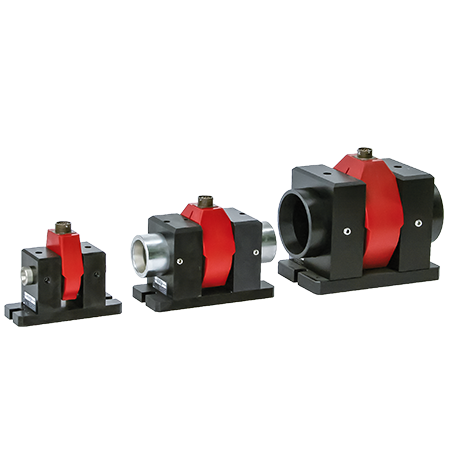

Encircling coil holders

Coil holders for encircling coils when testing non-ferrous material.

- Available in four sizes to accommodate different encircling coil sizes

- Test piece diameters: 0.1–175 mm (1/8 – 6 7/8″)

- Robust design

-

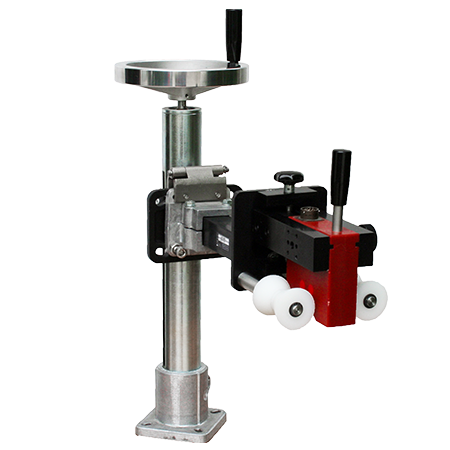

Segment coil holders

Various holders for segment coils are available with or without guide rollers, pneumatic tilt mechanism, and permanent magnets.

Special segment coil holder

For very large tubes that cannot be encircled by an encircling coil, a special coil holder is available that will hold 4 segment coils positioned in a square.

-

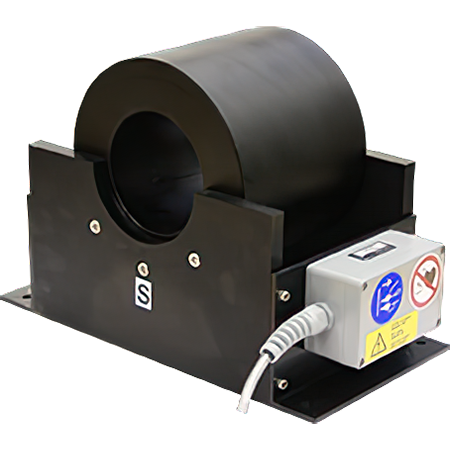

Magnetization units

An electromagnetic saturation unit magnetizes ferrous material for encircling inspection.

This unit holds the encircling coil and guide sleeves.

- Different sizes available to accommodate all encircling coil sizes

- Test piece diameters: 0.1–227 mm (1/8–8 7/8″)

-

Longitudinal magnetization units

This unit longitudinally magnetizes ferrous material for weld seam inspection. Available in various designs.

- Various lengths and sizes

- Test head can be raised pneumatically

- Low-cost magnetization units with permanent magnets also available

-

Demagnetization units

Demagnetization units are used to demagnetize material after inspection together with the electromagnetic saturation unit.

-

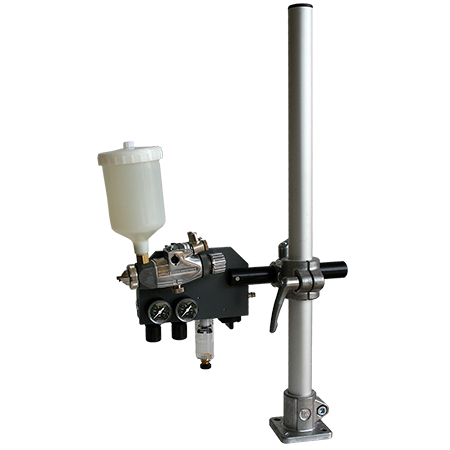

Paint markers

Paint markers mark the precise location of defects detected by test equipment. Fast response time. Available in different sizes.

-

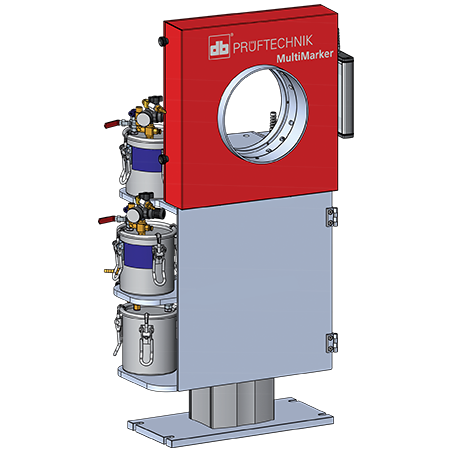

MultiMarker

This precision marker can mark defects on test pieces in four or eight segments along the circumference. An additional marker identifies the 0° position. Available in two models with five or nine markers.

-

Warning units

Warning units, e.g. horns or lamps, alert the user to material defects or system errors.

Interested?

Our technology experts are happy to answer your questions!