Highly sensitive inspection of black and bright metal bars and seamless tubes

- High precision for reliable test results

- Effective reduction of scrap and material expense

- Easy-to-use software and operation

- More than 15 years of experience with flux leakage technology

- Proven concept with protection sleeves against mechanical damage

- Easy-to-exchange parts for diameter changeover

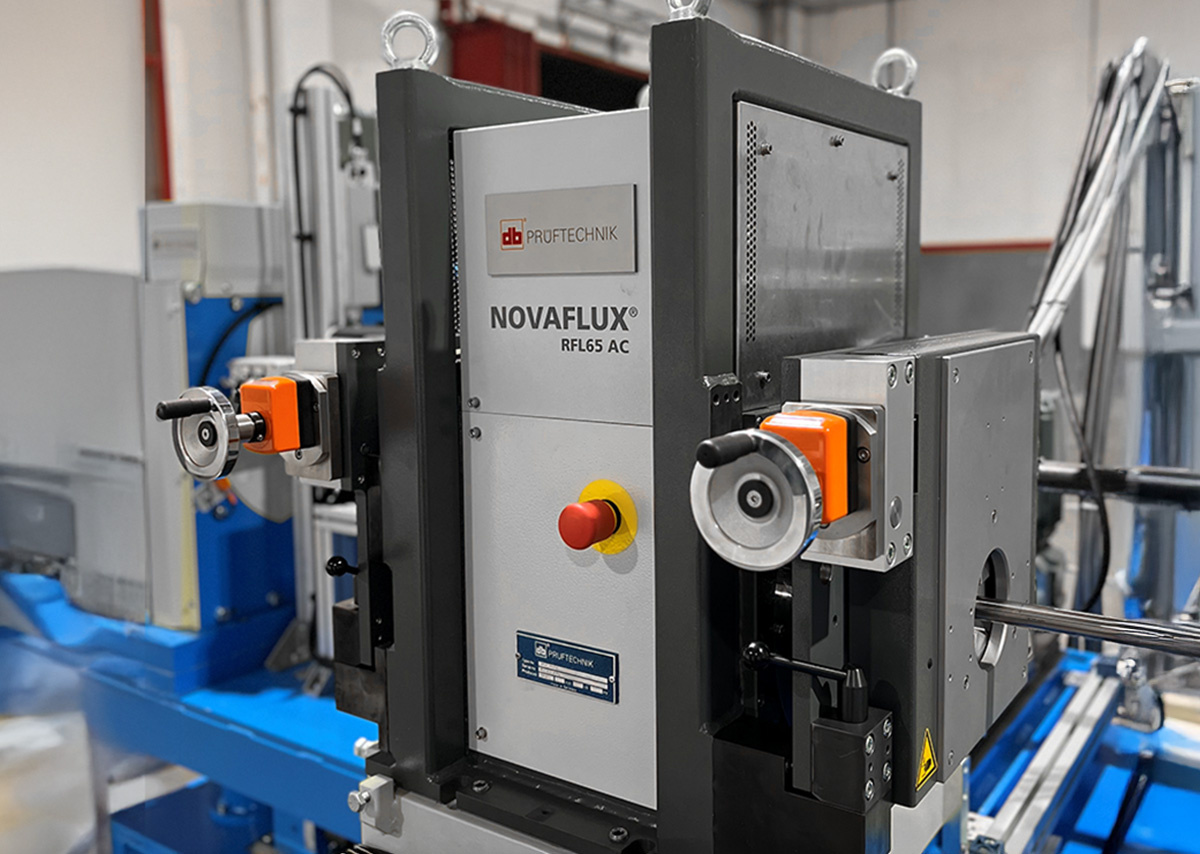

Ultimate bar testing with NOVAFLUX

- High-speed testing

- Detection of cracks as shallow as 0.1 mm in depth

- Detection of flaws on the inside and outside

- Reproducible inspection results, signal variation of less than 2 dB

- Customer-specific data interfaces available for integration in the network

Product description

As a producer of black or bright ferromagnetic metal bars, your customers demand high quality products – semi-finished products are often used in safety critical parts for public transport, automobiles, construction, etc. PRÜFTECHNIK NDT’s latest product line is the flux leakage-based NOVAFLUX inspection system. NOVAFLUX is used for the highly sensitive inspection of black and bright ferromagnetic metal bars and seamless tubes. Longitudinal defects from a depth of 0.1 mm can be found. It handles high production speeds of up to 2.6 m/s and features a user-friendly touchscreen for ease of operation. A detailed report of the test results permits further processing of defective yet repairable bars, thus increasing the yield.

NOVAFLUX comes in three models for different test piece diameters:

- NOVAFLUX RFL70NG: 5–70 mm

- NOVAFLUX RFL140NG: 10–140 mm

- NOVAFLUX RFL200NG: 40–200 mm

Interested?

Our technology experts are happy to answer your questions!